For the design of retaining walls, we define a large number of design variables in such a way that the stability and serviceability for the purpose are guaranteed.

In addition, our goal is to optimize the retaining wall for our client in terms of construction time and costs.

Through judicious selection of the structural elements and arranging them in the most efficient way, a lot of time and money can be saved in the course of the project. If, for example, the loads to be carried on by one anchor layer can be reduced, fewer anchors may be required – which will, understandably, have a positive effect on construction costs. If the number of anchors can be reduced, this means not only cost savings but also a shortening of the construction time.

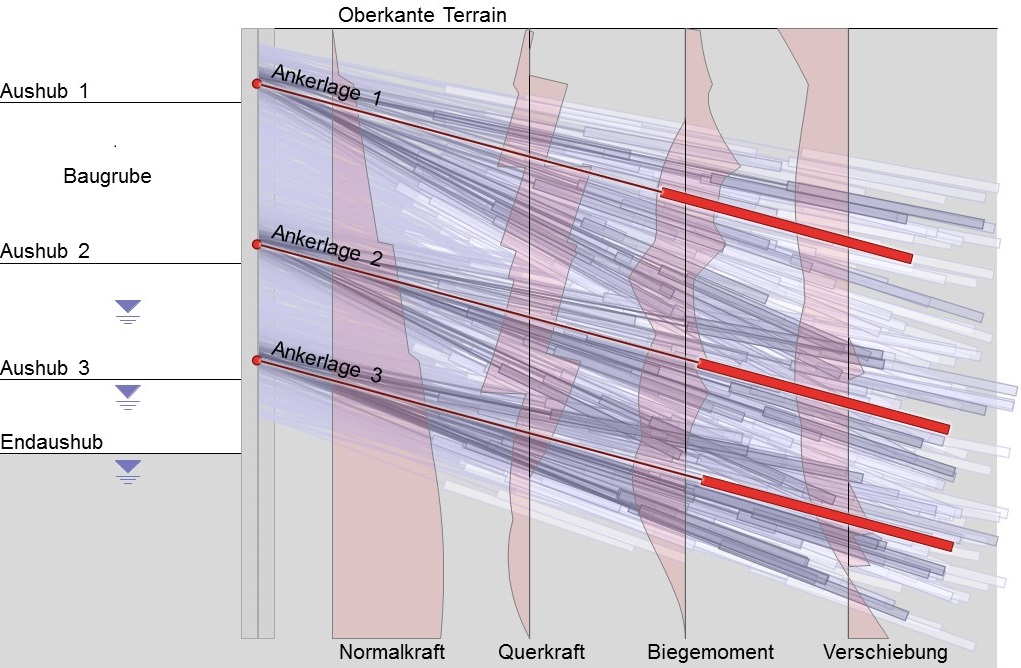

Illustration: Influence of the position of the lowest anchor position on the cutting sizes and anchor forces - a skilful choice and design of the excavation pit end can save a lot of money

We use mathematical optimization algorithms to facilitate the decision-making process and optimize costs, and these algorithms are linked to a standard statics software program. We create a cost function for each project individually that estimates the costs per linear meter of retaining wall. These costs include, among other factors, the material and manufacturing costs for the individual components of the construction.

Read more about the topic here.

We make use of the automated optimization of excavation pit retaining walls in our standard excavation pit projects and additionally offer this as an in-house service. The basis for this in-house service is often a computer-generated section (not yet optimized) through an excavation pit retaining wall.

Contact us per e-mail: laurent.pitteloud@gruner.ch or joerg.meier@gruner.ch

Illustration: Schematic system section with the examined combinations by the optimization algorithm

Illustration: We use a variety of optimization algorithms. The Particle Swarm Optimizer (PSO) is one of them: a PSO on a cost function F with two control variables (X1 and X2)

Illustration: Run of a particle swarm optimizer (in the diagram below: costs above the optimization progress)

Publications related to this reference:

- Meier, J. (2019): Optimierung von Baugrubenabschlüssen. 26. Darmstädter Geotechnik-Kolloquium, 12 pages. pdf

- Westermann, J.; Pitteloud, L.; Meier, J. (2020): Automatisierungsaspekte bei der Planung von Baugrube und Gründung eines Forschungszentrums. Bautechnik, Vol: 97, No: 12, S. 878-885. pdf

- Meier, J.; Pitteloud, L.; Irngartinger, S. (2021): Lötschberg Base Tunnel, Second Tube: Automated Cost Optimization of the Inner Lining. Tunnel 5/2021, Bauverlag, S. 22-35. pdf

- Pitteloud, L.; Darusman, D.; Meier, J. (2013): FE-Berechnung in der Geotechnik. 16. Symposium Bauwerksdynamik und Erschütterungsmessungen, 14.06.2013 an der EMPA Dübendorf, Zürich, 28 p. pdf

- Meier, J. (2013): Numerische Experimente zu Sicherheiten in der FEM. Herbsttagung der Geotechnik Schweiz, 07.11.2013, Biel, 11 Pages. pdf

Services

- Foundation and Geotechnical engineering